Russian

Gate Valve

Best gate valve for water systems

Industrial core choice for reliable sealing and efficient fluid control

In modern industrial pipeline systems, valves are important components for controlling fluid flow. Their type and performance play a decisive role in the operating efficiency and safety of the entire system. Among many industrial valves, (gate valve) has become the most widely used type of valve due to its simple structure, strong sealing performance and wide range of applications.

This article will focus on the keyword “Gate Valve”, deeply analyze its working principle, structural characteristics, technical advantages and typical application scenarios, and combine Google SEO strategy for keyword layout to help companies improve traffic conversion and brand authority.

Industrial gate valve manufacturers

- What is Gate Valve?

Gate Valve is a type of valve that opens or closes the fluid channel by moving the opening and closing parts (gate) vertically along the direction of the fluid channel. The main function of the gate valve is to cut off the on-off of the fluid medium, rather than adjusting the flow rate, and is suitable for fully open or fully closed working conditions.

It is widely used in many industries such as petrochemical, electric power, metallurgy, papermaking, medicine, urban water supply and drainage systems, and is the preferred cut-off device in medium, low pressure and even high pressure fluid control systems.

Metal seated gate valve suppliers

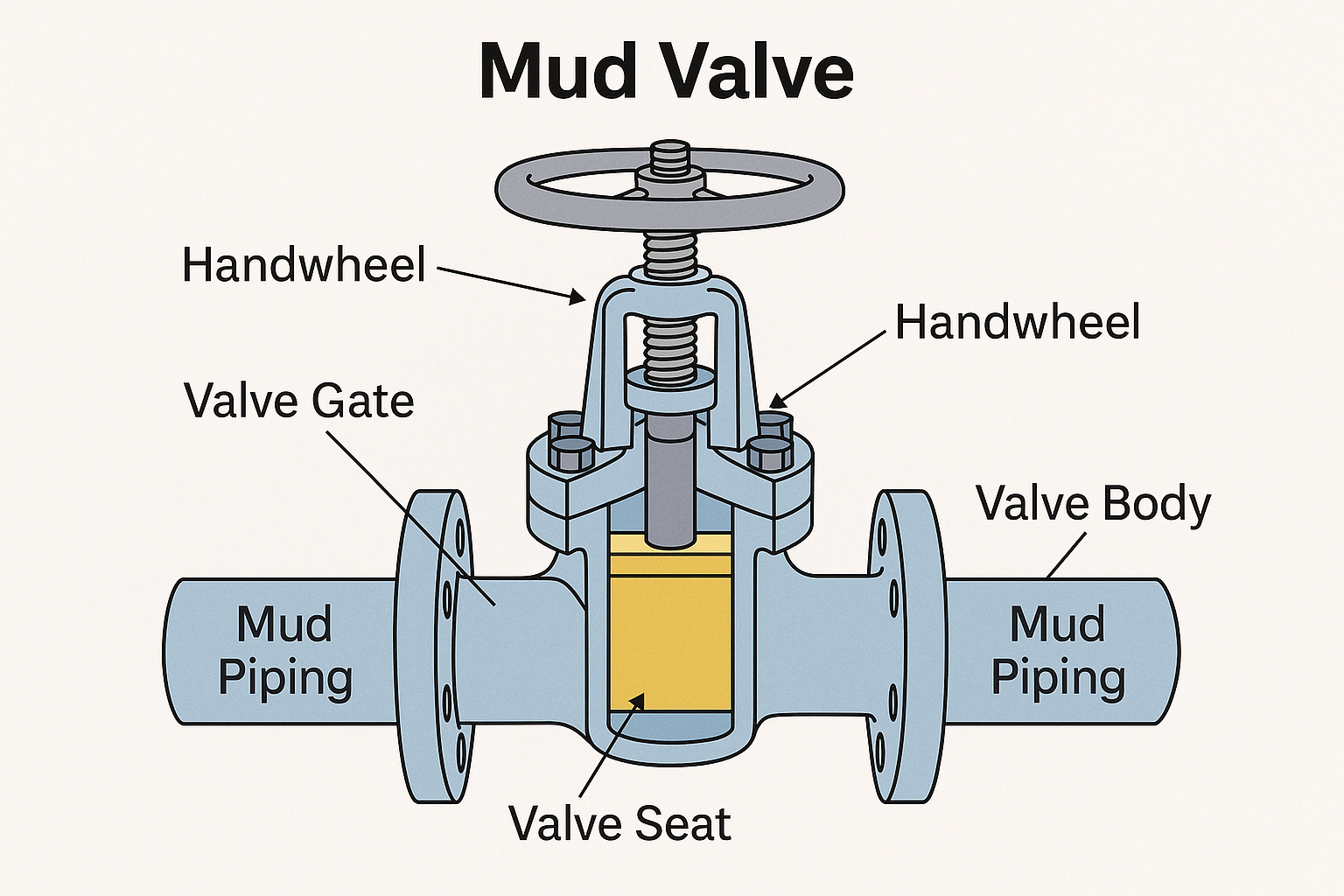

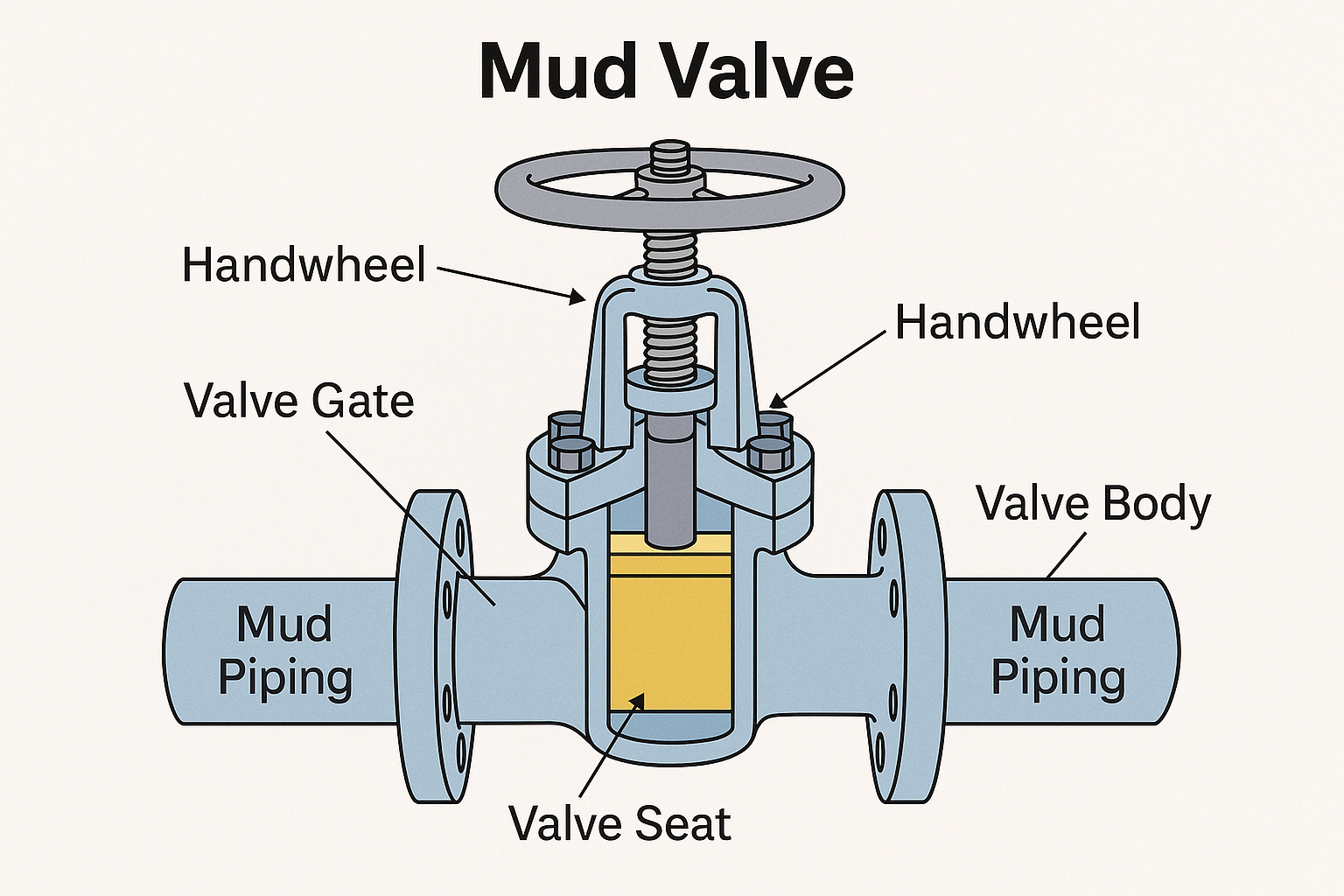

- Structural composition of Gate Valve

A complete set of Gate Valve usually includes the following core parts:

Valve body (Body): the main pressure-bearing component, mostly made of cast iron, stainless steel, carbon steel and other materials;

Gate (Gate): opening and closing parts, divided into wedge gate, parallel gate and other types;

Valve seat (Seat): sealing contact surface with gate to ensure zero leakage of fluid;

Valve stem (Stem): drives the gate to move up and down, connected to the handwheel or actuator;

Packing (Packing): prevents fluid from leaking from the valve stem;

Handwheel or electric actuator (Actuator): manual, electric or pneumatic operation to control opening and closing.

- Working principle of Gate Valve

When the handwheel or electric actuator is turned, the valve stem moves up and down, and the valve stem controls the gate to rise and fall. When the gate is fully raised, the channel is fully opened; when the gate drops to the bottom, it fits tightly with the valve seat to achieve complete closure.

Because its opening and closing action is “linear”, the fluid resistance is extremely small when it is opened, and the seal is excellent when it is closed. This is also the biggest feature that distinguishes Gate Valve from other valves such as ball valves and stop valves.

IV. Five major technical advantages of Gate Valve

- Full-diameter design, extremely small flow resistance

When the Gate Valve is fully open, there is almost no fluid resistance in the pipeline, and it will not cause pressure drop in the system, which greatly guarantees the fluid delivery efficiency, especially suitable for conveying viscous or particle-containing media.

- Excellent sealing performance

The high-quality metal valve seat with the wedge gate can achieve metal-to-metal sealing, which remains tight and leak-free under high temperature and high pressure environments, and is widely used in key process sections.

- Bidirectional flow, flexible installation

Gate Valve usually supports bidirectional sealing, and there is no flow direction restriction, which makes it more flexible during pipeline installation and has lower maintenance costs.

- Simple structure and easy maintenance

Compared with control valves or regulating valves with complex structures, Gate Valve has a simpler internal structure, fewer parts, easy disassembly, lower maintenance cost and longer cycle.

- Wide range of applicable pressure and temperature

From normal pressure to ultra-high pressure, from 50°C to 600°C, Gate Valve has corresponding materials and models to adapt, with strong adaptability, covering a variety of media from clean water to corrosive gases.

Differences between gate valves and ball valves

VI. How to choose high-quality Gate Valve?

When purchasing Gate Valve, it is recommended to consider the following dimensions:

Whether the valve body material is compatible with the medium;

Whether the sealing material is corrosion-resistant and high-temperature resistant;

Whether the operation mode is adapted to the system control requirements (manual, electric, pneumatic);

Whether the manufacturer has international certifications such as ISO/API/CE;

Whether the after-sales support and warranty period are complete.

We provide a full range of Gate Valve products, from standard models to highly customized engineering-grade gate valves, to meet the comprehensive requirements of different industries for quality, safety and efficiency.

VII. Conclusion: Gate Valve is the cornerstone of industrial control

In the increasingly complex and intelligent fluid control systems, Gate Valve still occupies an irreplaceable position with its excellent sealing ability, structural stability and wide applicability. It is not only a basic valve, but also a safe “gatekeeper” to ensure the stable operation of industrial systems.

If you are looking for high-quality, high-performance Gate Valve solutions, please contact professional suppliers for technical support and personalized recommendations to help your project run stably, efficiently and sustainably.

best gate valve for water system”, “industrial gate valve manufacturer”, “metal seated gate valve supplier”, “difference between gate valve and ball valve”